|

|

|

|

|

|

The

Zenith Zodiac Goes One Size Larger

Flying the new Zodiac

CH 601 XL

Text and photos by LeRoy Cook

Article

Reprint from CustomPlanes

magazine

(February 2001, pages 26 -31)

Subscriptions: 800-999-9718

When a kit aircraft design grows into a larger, more capable vehicle, it generally means the concept was right in the first place. A good engineer keeps expansion in mind when laying out a basic structure, knowing full well that someday it will have to be stretched, strengthened and enlarged. This was the route take by Chris Heintz of Zenair Ltd. in Midland, Ontario, who has been involved with the aerospace industry for many years when he designed the Zodiac CH 600 homebuilt in 1984. Over time, the basic kit evolved into the CH 601, with several derivatives.

The Zodiac CH 601 was sold as a finished product in Canada, where it is flown as an advanced ultralight, but under U.S. rules it had to be certified as a homebuilt with at least 51 percent of the aircraft built by the kit purchaser. Given homebuilders’ penchant for adding ever greater power and weight, a larger and heavier kit version was called for – something beyond the advanced ultralight category. To meet this need, a new XL version of the CH 601 has been introduced, offering more of everything Zodiac builders wanted in their all-metal two-seat low-wings.

Zodiac kits are produced in Mexico, Missouri, in the Zenith Aircraft plant, which was recently doubled in size to accommodate burgeoning demand. We dropped in to visit with two of Heintz's sons, Sebastien and Nicholas, who operate the Zenith facility, and took the opportunity to test-fly one of the new CH 601 XL prototypes.

Development of the XL

In the beginning, the Zodiac was a basic sportplane, powered by a Volkswagen car engine or, eventually, the two-stroke, 65-hp Rotax 582. As engine development progressed, most CH 601s were flown with Rotax 912 four-stroke powerplants. The wing was a deep, high-lift airfoil, and the characteristic Heintz tail featured an all-flying rudder, giving maximum control with minimum size. As time went on, an HD heavy-duty version was developed, stressed for + /-6 Gs.

The lust for speed resulted in an S-series speedwing option, featuring a 4-foot-shorter span and a thinner, tapered airfoil in the outboard section, with a scarfed tip for enhanced dihedral effect. Other evolutionary improvements included wing fuel tanks as an option to the fuselage tank and baggage bays that could be built into the inboard wing panels. The CH 601 HD and HDS were good airplanes, but there was still more room for growth in the design.

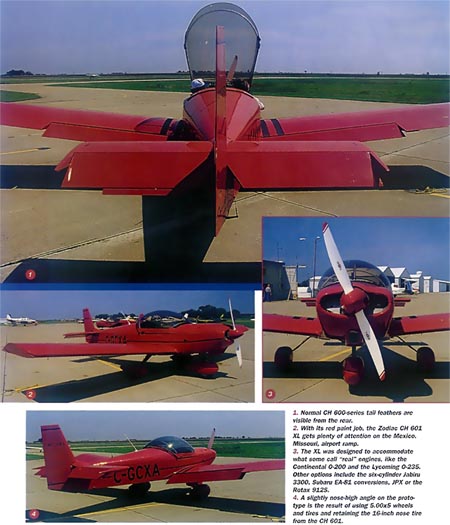

A certain segment of the kit airplane market wanted to use 'real' aircraft engines, a.k.a. the Continental 0-200 or the Lycoming 0-235. Grossing 100 pounds heavier than the CH 601, the CH 601 XL was designed to accommodate these engines. Other options for the XL include the six cylinder Jabiru 3300, Subaru EA-81 conversions, JPX or even the Rotax 912S, all in the 100-hp range.

The CH 601 XL has an entirely new wing that restores the span to a full 27 feet and eliminates the no-dihedral stub wing to which the main gear was attached. The new wing has the same dihedral from the root to the tip because the aluminum spring main gear legs are attached to fuselage structure rather than stub wings like the bungee-cord-cushioned main gear of the earlier Zodiacs.

The new wing also features electrically actuated flaps, which reduce the span of the hingeless ailerons Heintz favors; the wing's top skin serves as the hinge and gap seal, flexing a few degrees to achieve roll control. The 12-gallon fuel tanks are located forward of the spar. The new heavy-duty spring main gear on the prototype carried 5.00x5 wheels and tires, but it retained the 16-inch nose tire from the CH 601; we rather liked the jaunty nose-high angle this created.

The earlier Zodiacs had a neat tip-over canopy design that could be opened from either side for a choice of boarding access, but the occupants could still only board one at a time. The new XL canopy features a forward-tipping design with gas-spring assist, so both people can enter the cockpit simultaneously. Behind the seats, a 40-pound baggage area can handle routine cross-country gear. Most importantly, the XL’s cabin is 3 inches longer than the 601's, providing some extra legroom.

The flight controls are cable-operated. There is a vestigial fixed vertical fin atop the tailcone, but most of the tail is an all-moving surface that provides powerful yaw control. The 91-inch-wide horizontal tail, on the other hand, has large elevators attached to fixed stabilizers; Nicholas Heintz says no increase in tail area was needed when scaling up to the XL. The battery remains on the firewall, easily reached under the removable composite cowling.

Construction of the Zodiac CH 601 XL primarily employs 6061-T6 aluminum, stitched together by a gazillion heavy-duty pulled rivets, rather than bucked rivets. In keeping with the Chris Heintz philosophy that his airplanes be constructed with only normal hand tools like a file, snips, drill and blind rivet gun, the CH 601 XL kit requires no welding and no complex driven riveting (the engine mount and wing spar come already assembled). However, for the purist and scrounger, plans are available, as well as full and sectionalized kits.

The build time is said to be as little as 400 hours, and, indeed, Zodiacs have been built in a week during airshows as demonstration projects but one can easily double that figure if painstaking finish work is desired. The space required is fairly modest, thanks to the still-diminutive size of the airplane, particularly before the wings are attached.

|

| Nicholas Heintz lowered the flaps slightly to stay next to the Cessna 150 photo plane. Below is the Missouri countryside near Zenith Aircraft’s Mexico plant. |

Going Flying

Our friend Nicholas Heintz didn't have to ask twice when we started hanging around his new bright-red CH 601 XL demonstrator, built in Canada as a proof-of-concept machine. Charlie X-ray Alpha was still warm from its previous showing, so we leapt onto the wing-walk (there is no boarding step behind the wing) and slipped into the seat.

We found a 44-inch-wide cabin with only the middle few inches taken up by a central tunnel for the control linkages. This early prototype wasn't optimized as a full-dress demo airplane, but it wasn't a barebones airplane either. Avionics consisted of a PS Engineering PM-1000II intercom/audio panel and a Bendix/King KLX 135 GPS/com radio.

The roomy panel had space for gyro instruments, although they were not installed. The pitch trim switch was near the throttle. Heintz said he would prefer the smaller Mitchell engine gauge cluster that would open up a spot on the panel for a center-mounted radio. The wing tanks did, however, allow for unlimited panel options because there's no header tank behind the panel. The fuel selector is mounted on the floor between the pilots.

The center-mounted control column is another special Chris Heintz feature, with a Y-shaped handle branching to either seat. This unique system clears up floor space and allows either pilot equal access. We did, however, have toe brakes only on the left side. No matter; once underway, we found the XL was easy to handle with a low taxi speed. The nosegear steering was quick and positive and the ride was well cushioned, even on rough pavement. The canopy can be left ajar for added ventilation on the ground.

|

A quick run-up yielded no surprises. A real magneto test at 1700 rpm replaced the Rotax 912's 3000-rpm check of CDI modules. There was no vacuum system installed on the VFR panel of C-GCXA. Electric pitch and rudder trim were set to neutral, and the boost pump was flipped on. No flaps are used for takeoff.

After the canopy was snugged shut and the latching was verified, we headed down the Mexico runway under the full cry of 116 Lycoming horsepower. Liftoff at 65 knots was accomplished in about 800 feet of runway -- a bit late in the execution due to our preoccupation with adjusting the attitude with the central stick. The tendency to PIO from light pitch forces was handled by simply freezing the stick in place and letting the airplane settle down. A climbout at 90 knots yielded 600 to 700 fpm in the summer turbulence (about double what a Cessna 150 would do under similar conditions).

Leveling out at 3000 feet, we enjoyed the fighter-like view through the bronze-tint fishbowl canopy. Wrapping the XL into steep turns and hauling back on the yoke seems natural from the left seat, with the lockable throttle in the left hand. The pitch and yaw controls were lighter than the roll mode, but not overly sensitive.

We set up 2500 rpm to see 117 knots [134 mph] indicated, or about 126 knots TAS [145 mph]. At a more leisurely 2400 rpm, we achieved 110 knots, or roughly 118 knots TAS. It's a quick little airplane, but when we slowed it down with flaps up, we were able to maneuver at 60 knots with no hint of a stall. Working the angle of attack higher, the airplane broke with plenty of notice at 50 knots; lowering the flaps makes only a slight difference in stall speed, but it does lower the nose attitude for a more comfortable approach. The top of the white arc for flaps is at 100 knots, while the yellow arc starts at 140 knots.

Returning to the airport, there wasn't much to discover about the airplane's traffic-pattern habits; it was docile at a time when the pilot's attention can easily be diverted elsewhere. We felt comfortable with 80 knots in the pattern, running about 75 knots on final with flaps extended. Touchdown at 60 knots had us turning off in 1000 feet with negligible braking.

The CH 601 XL is an excellent choice for an economical two-seat cross-country cruiser, particularly if you like metal airplanes. It runs fast, carries a decent load and offers a comfortable cabin. As you might expect from a designer who has several certificated airplanes to his credit, it flies with no surprises, just as it should. Check it out for fun on a budget.

Article reprinted from CustomPlanes magazine, February 2001. "The Zenith Zodiac goes one size larger," by LeRoy Cook, pages 26 - 31.

Zenith Aircraft at Work and Play around the World... Click here for photos and stories Zenith Aircraft

Company |

© Zenith Aircraft Company: 2008-09-10