|

||||||

ZENITH STOL CH 801

PILOT REPORT Reprinted from Aviation

Canada magazine (formerly Aviation Quarterly), Fall 1999 STRAPPING INTO the new four-place 801 STOL, I was expecting the same flight characteristics and performance as the now diminutive 701. Well, I was half right. The 801 has all of the desirable handling during stalls, slow flight, landing and takeoff as the two-place, but performance has made a quantum leap. With 29 years of kit production behind them and thousands of builders worldwide, Zenith Aircraft understands what builder/pilots need and they fill that niche very effectively while never compromising built-in handling characteristics that maximize flight safety. Designer Chris Heintz isn't interested in glitz and glamour nor in maximizing cruise speeds as primary considerations. Instead, he concentrates on ease of building, ease of flying and easing up on pilot wallets. The very successful international sales record proves that he is in tune with the world's aviation needs.

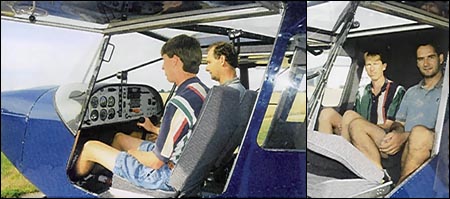

Like the 400 CH 701s flying today, the 801 is optimized for short field operations, and the fields don't have to be smooth because the double-cantilever spring-leaf main gear and large 800 tires can tame rough terrain with ease. Although I was surprised to see a tricycle gear on this heavy hauler/bushplane Chris explains that his choice was based on numerous factors. Most aviators are not comfortable in conventional tail-draggers, and the nose gear and upswept rear fuselage allow the 801 to rotate to steep angles of attack for super-short takeoffs and landings. To achieve the angles necessary to lift off at low speeds with a tail-dragger, he would have had to install a ridiculously long, heavy main gear. Additionally, the tricycle gear makes cabin access much easier and it certainly improves visibility on and near the ground. Chris believes that no other affordable and easy-to-build kitplane can carry the 1,000pound payload off the field that the CH 801 can. (The Christavia Mk 4 comes to mind as a competitor for performance; however that tube-and-fabric aircraft requires thousands of hours to build from scratch.) The proven all-metal construction requires only basic tools and clecos to hold sections together. The use of Avex pull-type rivets greatly reduces the challenges associated with other forms of riveting. Chris's background as an aeronautical engineer ensures that his aircraft are solid and designed for everyday use with wear and tear kept to a minimum. Check out some of his kits with lots of flying time on them; compared to its competitors, the Zenith holds up very well. Chris is responsible for a lot of great ideas that are so logical you'll wonder why others haven't incorporated them before. The cabin is spacious, and the front seats slide back easily to accommodate large pilots. Seats lock on their tracks with a simple rod that slides across the seat bottoms: simple, but perfectly logical-and safe. The cockpit doors fold up against the bottom of the wing and, coupled with handles, allow easy entry. They can be quickly removed and the aircraft flown with no speed restrictions-but lots of ventilation. The rear seats are also removable and the area is apparently large enough for 50-gallon drums - although you'll be limited to one full one - even with the generous aft seat and baggage allowance of 400 pounds. (Cabin width is 44 inches, and the back seats are comfortable for this 200-pound, 70-inch-tall pilot.) I noted the static friction in the controls was very low, which hints at light control forces during the anticipated flight. Company representative Roger Dubbert and I conducted our evaluation flight at Arlington with a full fuel load of 30 U.S. gallons (60 gallons optional), placing us 460 pounds under gross - obviously a true four-place aircraft. The seat was firm and very comfortable and, compared to soft seats that produce a lot of rump fatigue on long flights, it was perfectly suited to my taste. Visibility was excellent thanks to the tricycle-geared stance, and directional control with the nosewheel steering was superb-especially with augmentation from the toe brakes. The pedals felt fairly heavy with the weight of the 180 hp Lycoming bearing down, but the turning radius was very tight and control response just perfect. I found the noise level high with the big donk; however, Roger advised that production kits would have a thicker windscreen to reduce the audible levels. Besides, I think a lot of builders will choose the smaller, lighter, quieter Lycoming 0-320 for their 801 projects, as 150 to 160 hp will be adequate for most operators. (The first prototype sports this engine and cruises at 120 mph indicated with a cruise prop.)

The throttle on the left extremity of the generous IFR-capable panel and the Y-shaped control yoke mounted between the seats remove any objects from in front of the pilot and occupants as a concession to crashworthiness. The single Y column mounted on the center line also reduces weight and complexity in the control system. Roger suggested a rotation speed of 40 to 45 mph for a flapless short-field takeoff with the elevator trim set in the middle position. However, without weight in the back seats, I didn't apply enough aft stick pressure on my takeoff due to the heavy nose weight of the Lycoming. Our takeoff roll was 600 feet into a 10-mph quartering headwind. Nonetheless, I have no doubt the 801 could easily levitate in 300 feet with adequate back pressure applied, because the acceleration was a joy to behold with the 180-hp engine. Our climb angle resulted in a lot of open mouths amongst the crowd. At 70 mph we were showing 800 fpm on the clock - the obstacle-clearance climb angle is very steep. We passed the end of the runway well above 1,000 feet AGL and converted to a cruise climb of 90 mph and 800 fpm -perhaps the VSI was stuck! I quickly found that the 801 has beautifully balanced controls that produce very crisp response. It's a surprisingly nimble and fun aircraft to fly! While the STOL is neither designed nor recommended for aerobatics, a comment from Roger later in the flight led me to make some large flight excursions in terms of pitch and roll, and I found that the aircraft maintained its substantial, forgiving safety margins while providing the capability to "soar with the eagles." With the installed climb propeller, we leveled off to find that the 801 is capable of an indicated airspeed of 110 mph at 2,500 rpm at 3,000 feet. This would translate into a true airspeed of approximately 125 mph at 8,000 feet. Not too shabby for a STOL design! As mentioned earlier, unless you need the ability to get airborne in distances roughly equivalent to Santa Claus's heavier-than-air machine, you could likely install a smaller engine with a cruise prop and capture greater cost efficiencies. (Incidentally, Roger flew C-GECX all the way from Mexico, Missouri, and averaged fuel flows in the 7.5- to 8-gallon range at 2,500 rpm. And those are the tiny U.S. gallons!) The controls were light and responsive at all speeds, and the trim forces so light throughout the speed spectrum that I could have flown the entire flight without using any trim. In the dense Saturday traffic around the fly-in I was delighted to find that the overhead skylight provided excellent visibility as we cranked and banked during the testing. Practically speaking, the wing won't stall during cruise power settings unless the aircraft is placed in a steep, high-G "dogfight" turn. We accomplished the steepest of turns, and the aircraft was completely forgiving. The various stalls were preceded by the mildest of buffets and the nose nodded downward only slightly. No hints of wing drop or secondary stalls were perceptible throughout the range of stalls, and the ailerons remained effective even during the power-on, full-flap stall at 30 mph indicated. Well, it was sort of a stall. The aircraft buffeted slightly when the stick was pulled fully back; but the 801 was almost hovering as the nose held its exaggerated skyward tilt with full controllability. It would be difficult to get into trouble by stalling inadvertently in this aircraft. The power-off flapless stall occurred at 50 mph and, with a touch of approach power, at 45 mph. With flap, the power-off stall was reduced to 40 mph. The difference of 10 mph with flaps is a strong indication of their effectiveness on this high-lift wing. Incidentally, the short wingspan of 31 feet is able to create more than adequate lift due to the high-lift coefficient of 3.1 provided by the leading edge slats and Junkers-style aileron and flaps that significantly increase the wing camber.

Speaking of the hanging flaps, there are a few observations worth noting. During flaps extension, the nose pitches upward significantly (and, of course, downward during retraction); however, the resulting trim force is easy to overcome until the pilot has the opportunity to trim, and while the flaps produce a considerably higher lift coefficient they do not provide a lot of drag. Consequently, pilots who wish to make very steep approaches over obstacles will likely want to use the STOL’s sideslipping capabilities in concert with the flaps. Personally, I love sideslipping, as it improves visibility downward on all aircraft. In the case of the 801, the very powerful rudder allows moderate to high sideslip angles - a very definite blessing in crosswinds. The electric flap extension speed of 80 mph isn't very high, especially considering that the STOL is a very good glider - but one always has the option of sideslipping to reduce speed if the flap extension needs to be rushed. Also, I found the yellow line speed (Vmo) rather low at 100 mph indicated, since the STOL is likely going to be cruising at significantly higher speeds. But these are small considerations in terms of aircraft performance. The heavy traffic dictated only one landing, so I set up for a short field touchdown carrying 55 to 60 mph on final with a threshold crossing speed of 50.The STOL plopped down at a comfortable 45 indicated and could have been stopped in 30 feet without challenging the brakes. As for options, the 801 can be equipped with skis, floats and a belly pod with a 300-pound capacity, to name a few desirable items As a member of the amateur-built category, the aircraft can be greatly modified to personalize its uses. Short (field) conclusions If short fields, soft fields, rough fields or obstacle-lined fields are your choice (or necessity) for an airport, you have to consider the 801 as a prime candidate for the four-place certified engine-powered marketplace. The 801 shares the very popular 701's concepts-but not one of its parts. The implied high safety margins with exceptional low-speed handling make the 801 an excellent selection for low-time pilots, and even high-timers will appreciate its handling qualities and short-field competence. Moreover, the relatively quick build kit and reasonable price will allow aviators to assemble and fly this four-place load hauler for under Cdn$50,000. This is exceptional value when a four-place factory-built aircraft costs more than three times as much. |

||||||

|